Magnetic Sense sensors are deployed in various markets and diverse applications

Our patented sensors and sensor solutions for measuring and controlling torque, tensile, and compressive forces help increase efficiency in many application areas and minimize costs. Measurement can be conducted on different shafts and test bodies, whether static or rotating, making no difference to our sensor. The sensor can be used in all torque ranges. The design of the OEM measuring cell can be customized to miniaturized form factors specific to each customer. The measurement method is applicable to any shaft diameter. Additionally, they enhance safety and support intelligent digital systems.

Magnetic Sense sensors offer outstanding performance and reliability. The cornerstone of the torque sensor is planar coils manufactured in specific processes, generating a magnetic field influenced by the ferromagnetic properties of the test piece.

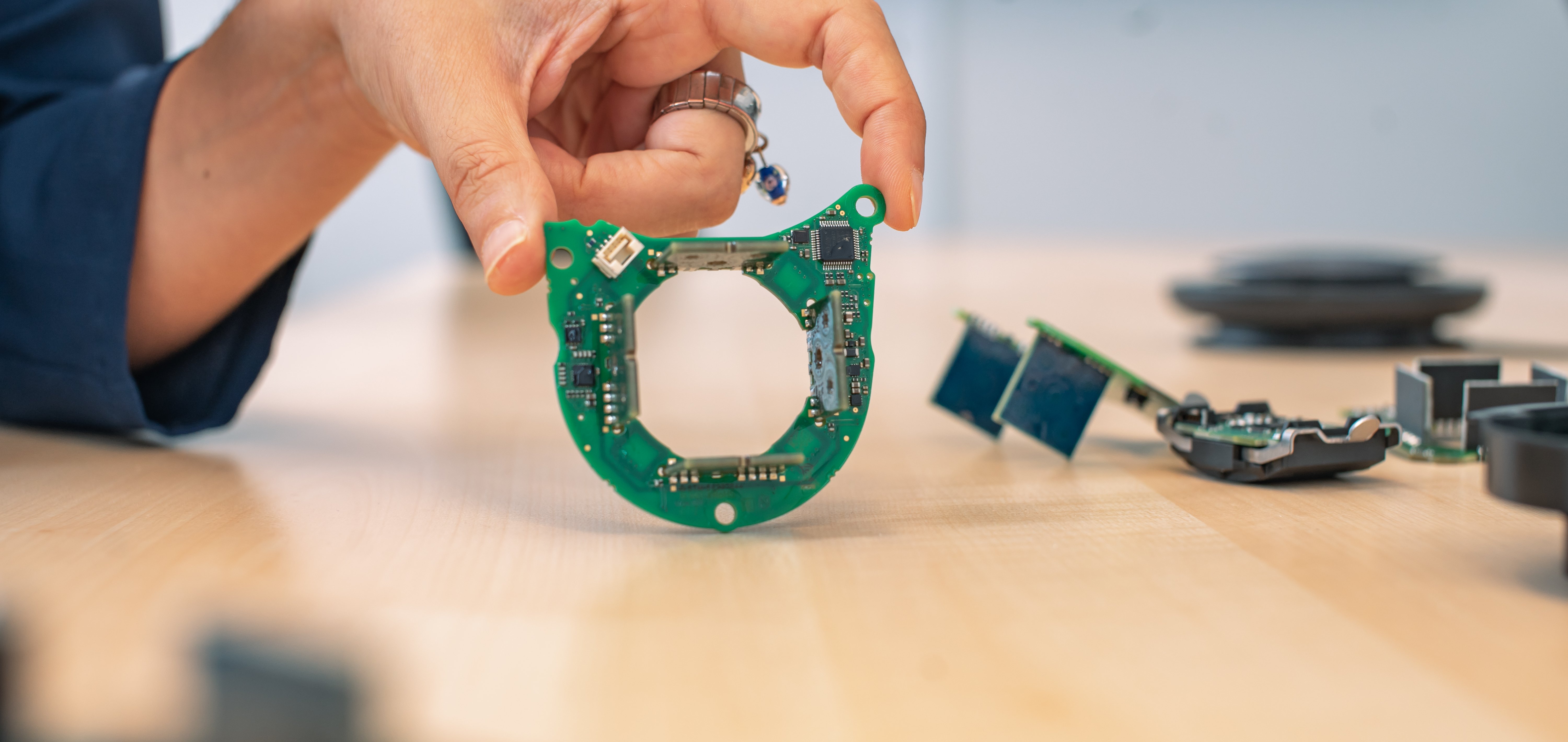

Construction of the torque sensor:

Controller: Powerful signal processing allows small signals to be digitized and processed.

Sensor element: The magnetic field for measurement is generated by planar coil inductors.

Sensor housing: Application-specific design of the sensor housing ensures that customer space requirements can be met.

Dimensions and measurements

The sizing of the sensor depends on the customer's spatial requirements. Various customer requirements can be met through a modular kit. Even small dimensions can be achieved through close collaboration.

Direct integration into the customer's application can also be realized through appropriate design and dimensioning of the mechanical and electrical interfaces.

Signal and supply of the torque sensor

The sensor requires a 5V power supply. The current consumption is approximately 100mA at 5V. The output signal for the customer can be specifically designed.

Standard interfaces already implemented (SPI, UART, CAN) can be configured according to customer specifications.

Signal bandwidth of the torque sensor

The standard signal bandwidth of the sensor is 100Hz with a signal-to-noise ratio of < 0.1% FS.

By adjusting the internal signal processing, the output signal can be adjusted to up to 1kHz.

What forces can the sensor measure?

The sizing and orientation of the measuring coils define which mechanical forces can be measured. Customers who require measurement of multiple force vectors, such as torque and axial forces, can be accommodated through a customized design and appropriate configuration of the sensor. Additionally, bending forces can be determined through the analysis of measurement data. The sensor technology is designed in such a way that various measurement tasks can be addressed through minor constructive adjustments.

Material of the test object

An important requirement for the use of the technology is that the measuring shaft is made of a ferromagnetic material and is hardened. We are happy to recommend suitable materials for the shafts and the hardening in an initial discussion. It is important for our customers that the measuring shaft is part of the sensor and that the system must be coordinated in a collaboration.

The dimensioning of the shaft and the safety factor for overload determine the expected accuracies in the application.

0 Comments