Electric Motor Operation

There are electric motors everywhere! Nearly all of the mechanical motion you observe in your home is powered by an AC (alternating current) or DC (direct current) electric motor itself. We'll examine both kinds in this piece. You can learn a lot about magnets, electromagnets, and electricity in general by studying how a motor operates. Magnets are used by electric motors to generate motion. You are aware of the basic law of all magnets if you have ever played with them: Likes repel and opposites attract. In other words, if you have two bar magnets with the ends labeled "north" and "south," the north end of one will draw in the south end of the other.Conversely, one magnet's north end will resist the other's north end (and south will repel south). These attracting and repelling forces produce rotational motion inside an electric motor.

Inside an Electric Motor

As previously said, you will come across two different kinds of electric motors: alternating current and direct current. Direct current, or DC, motors, which are still in use today, were initially created in the middle of the 1800s.

Six components make up a basic motor:

Axle

Brushes

Stator

Rotor

Commutator

DC power source

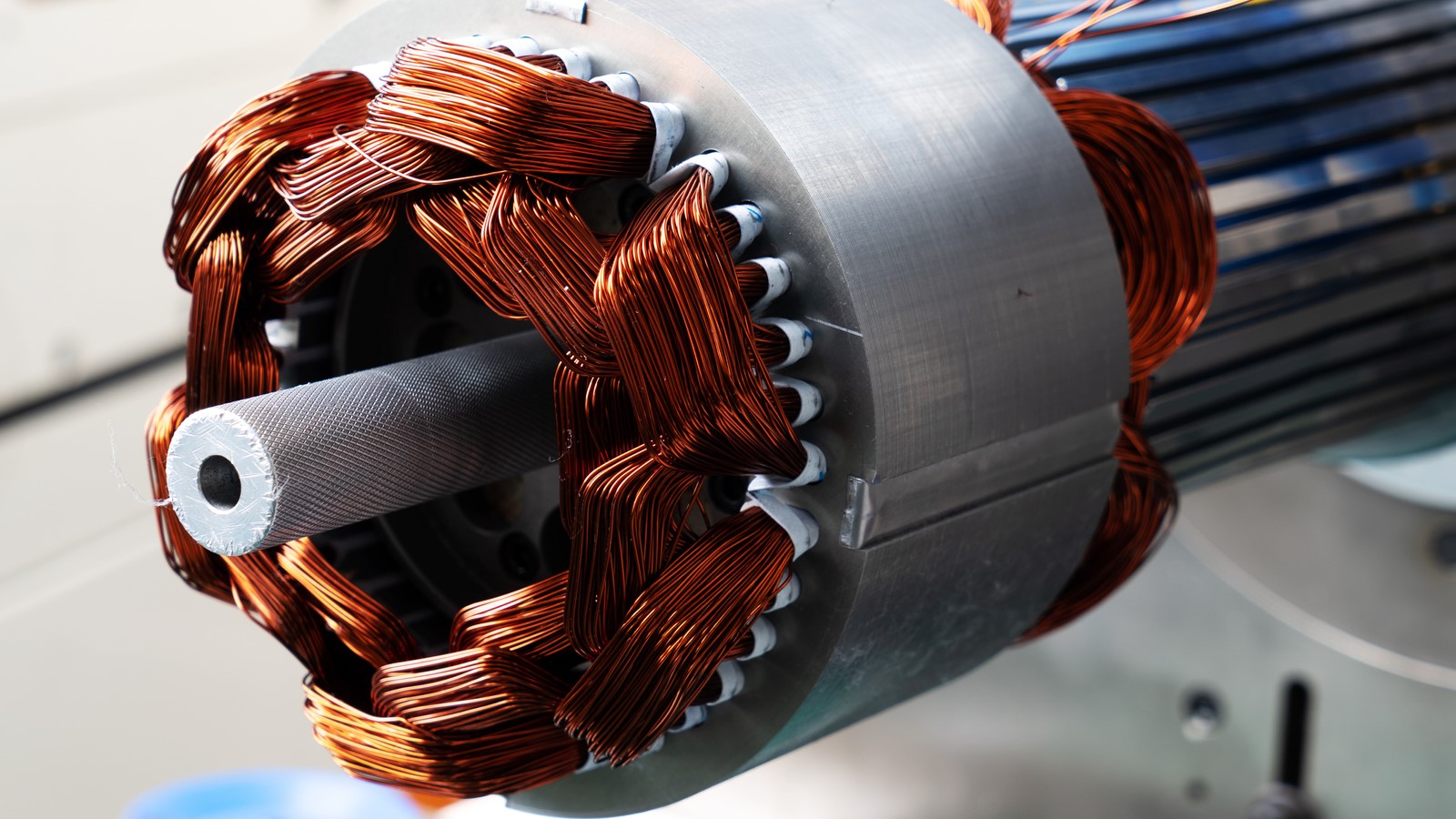

The stator, a stationary permanent magnet, is located on the exterior of a DC motor. The rotor, which moves, is the internal component. Here, the stator is comparable to the horseshoe magnet, and the rotor is comparable to the nail in our earlier example. A transient electromagnetic field produced by DC power passing through the rotor interacts with the stator's permanent magnetic field. The commutator's function is to maintain the field's polarity flipping, which keeps the rotor turning. The torque required to generate mechanical power is thus produced.

Toy Motor

The little toy DC motor in the picture has two battery leads and is approximately the size of a cent. The axle will spin if the motor's battery lines are connected to a battery. It will spin in the opposite way if the leads are switched. Two tabs hold the nylon end cap in place. As the motor rotates, power is transferred from the battery to the commutator via the motor's brushes inside the end cap. The commutator and rotor are supported by the axle. Three electromagnets make up the rotor in this instance. This motor's armature consists of a stack of thin metal plates with thin copper wire wound around each of the rotor's three poles. Each of the three terminals is connected to one plate of the commutator after the two ends of each wire—one for each pole—are connected to a terminal. The stator is the last component of any DC electric motor. The can itself and two bent permanent magnets combine to make this motor. The field is the stator in DC motors, while the armature is the rotor.

Brushes, Commutator, and Rotor

The rotor functions similarly to the nail in our electromagnet diagram, as we previously mentioned. The axle is also connected to the commutator. Just two plates fastened to the axle make up the commutator. These plates give the electromagnet's coil its two connections. Commutator and brushes are the two components that make up an electric motor's "flipping the electric field" function. The diagram illustrates how the brushes (in red) and commutator (in green) cooperate to allow current to pass to the electromagnet and to reverse the direction of electron flow at precisely the proper time. The commutator's contacts rotate with the magnet because they are fastened to the electromagnet's axle. The brushes are merely two carbon or springy metal parts that come into touch with the commutator's contacts.

Bringing Everything Together

A complete electric motor is what you get when you combine all of these components. The electromagnet's poles must flip when the rotor moves through the horizontal position. The electromagnet's north pole is constantly above the axle due to the flip, which allows it to attract the stator's south pole and repel the stator's north pole. The rotor often has three poles instead of the two that are depicted in this article. A motor should have three poles for two excellent reasons: It improves the dynamics of the motor. In a two-pole motor, you may envision the rotor becoming "stuck" at the balance point, which is precisely horizontal between the stator's two poles when the motor first starts. A three-pole motor never does that. In a two-pole motor, the commutator shorts each time it reaches the point where it flips the field.This shorting unnecessarily drains the battery and loses energy. This issue is also resolved with a three-pole motor.

The Operation of an AC Motor

We will now examine the AC motor. Instead of using direct current, AC motors use alternating current. It still uses electromagnetism and reversing magnetic fields to produce mechanical power, and it shares many components with a DC motor.

An AC motor's components are the stator, rotor, solid axle coils, and Cage of squirrels

An AC motor's stator winding essentially performs the function of a DC motor's rotor. In this instance, the spinning magnetic field is produced by a ring of electromagnets that are paired and sequentially powered. A DC motor's rotor is connected to the battery, as you may recall. However, an AC motor's rotor is not directly connected to a power supply. It has no brushes either. Rather, it frequently makes use of a squirrel cage. Yes, you read correctly. An AC motor's squirrel cage is made up of rotor bars that are joined to two rings, one at each end. It resembles something a squirrel or mouse in a cage would run through. The stator houses the squirrel cage rotor. An electromagnetic field is produced as AC power passes through the stator. The squirrel cage rotor's bars react to the stator's poles flipping because they are conductors. The rotor revolves in this manner, producing its own magnetic field.

AC Stator and Rotor

The rotor's constant pursuit of catch-up is crucial in an AC induction motor, where the stator's field induces the rotor's field. It rotates in search of a stable state because it is constantly searching for it. However, the stator's AC-powered electromagnetic field will always be a bit quicker than the rotor's field. The rotor's rotation generates the torque required to provide mechanical power for turning a fan or an automobile's wheels. Instead of using a wire-wrapped rotor, some AC motors use a wound rotor.However, the squirrel cage kind is more prevalent. In either scenario, an AC motor just has one moving part, which reduces the number of parts that require maintenance or replacement.

0 Comments