An Introduction to Synchronous Motors

The Magnetic Slip

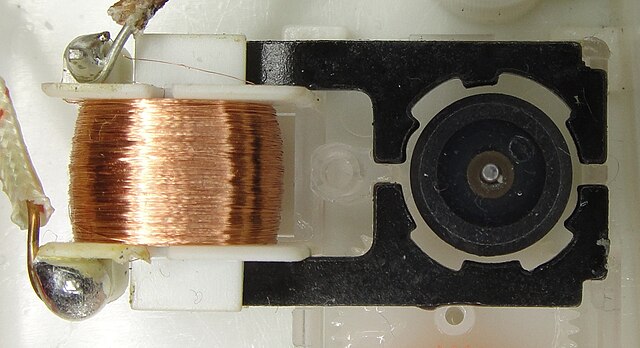

Induction AC motors feature magnetic slip, in contrast to synchronous AC motors. This implies that there will be a magnetic lag in the relative speed of the rotor and stator rotating magnetic flux. Synchronous rotors, which are based on the design and speed at which they were built, include field coils with a stationary magnetic pole on each of the successive poles to prevent this slip. Because of this configuration, the rotor's magnetic poles remain "in sync" with the stator windings' rotating magnetic field.

In order to power the revolving field coils on the synchronous rotor, older synchronous motors were built with slip rings and were induced by an external source, usually an onboard DC generator that sent DC voltage directly to the slip rings. The majority of synchronous motors nowadays use a diode wheel that transforms DC voltage from an onboard AC generator mounted on the rotor's main shaft. These motors can be brushless or self-excited. The motor is started in its application by means of electronic starting components that are external to the motor and coordinated.

The Amortisseur Windings and Power Factor

It's crucial to understand that synchronous motors can operate with either a leading or lagging power factor. A trailing power factor will result from the rotating field being underexcited. Right now, the air gap flux is insufficient. On the other hand, a leading power factor may result from excessive excitation. In this instance, the air gap flux exceeds the typical excitation required to maintain the motor's power factor.

A synchronous motor's rotor is engineered with Amortisseur Windings (AW) to help reduce transient oscillations brought on by variations in load. These windings are placed onto the field coil iron's upper outside border. When the motor is starting up without any load, like in a compressor application, the amortisseur windings also help the rotor.

Before the main field coils are ignited with DC voltage to synchronize the speed with the stator windings, the AW serves as an induction winding on the rotor to help rotate and get it up to speed.The load can then be applied to the motor after synchronization. The AW won't carry current when the motor reaches synchronous speed because there won't be any slip. Any departure from synchronous speed, however, will result in slip, produce a current in the AW, and reduce torque. As a result, the transient oscillations will be less intense when the rotor is spinning.

0 Comments